By H-Lift | 13 March 2023 | 0 Comments

Hand Operated Chain Hoists

Hand operated chain hoists

Hand operated chain hoists are self-sustaining lifting mechanisms which provide an easy means of manually raising loads with acceptable operative effort. In the case of the larger capacities, they may be intended and arranged for more than one operative. Most chain hoists are designed for vertical lifting operations where the load is positioned directly below the hook although some are designed for use at an angle. They may be used in association with girder trolleys to move suspended loads along suitable tracks, e.g. runways.

The lower capacities are ideal for general use whilst the larger capacities are suitable for less frequent operations. Due to their comparative light weight and ease of installation, they are often used for temporary applications. They are also ideal for applications where no power source is available and are commonly used for maintenance purposes, in general workshops and storage areas where a lifting facility is required.

All modern hand operated chain hoists have a brake mechanism which makes them self-sustaining. However, some old types were not self-sustaining and these types are no longer considered suitable for use. Some national standards require hand operated chain hoists to have load limited devices fitted.

Method of Attachment

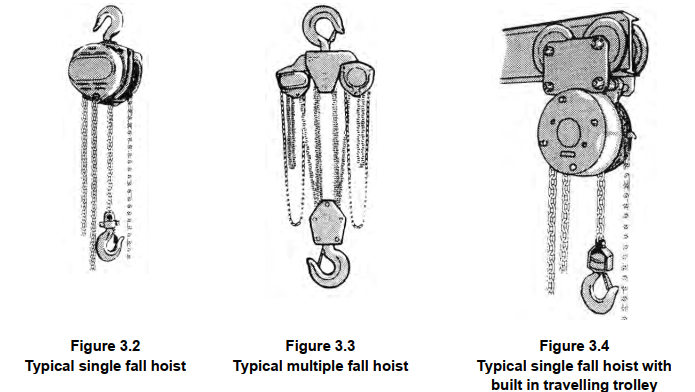

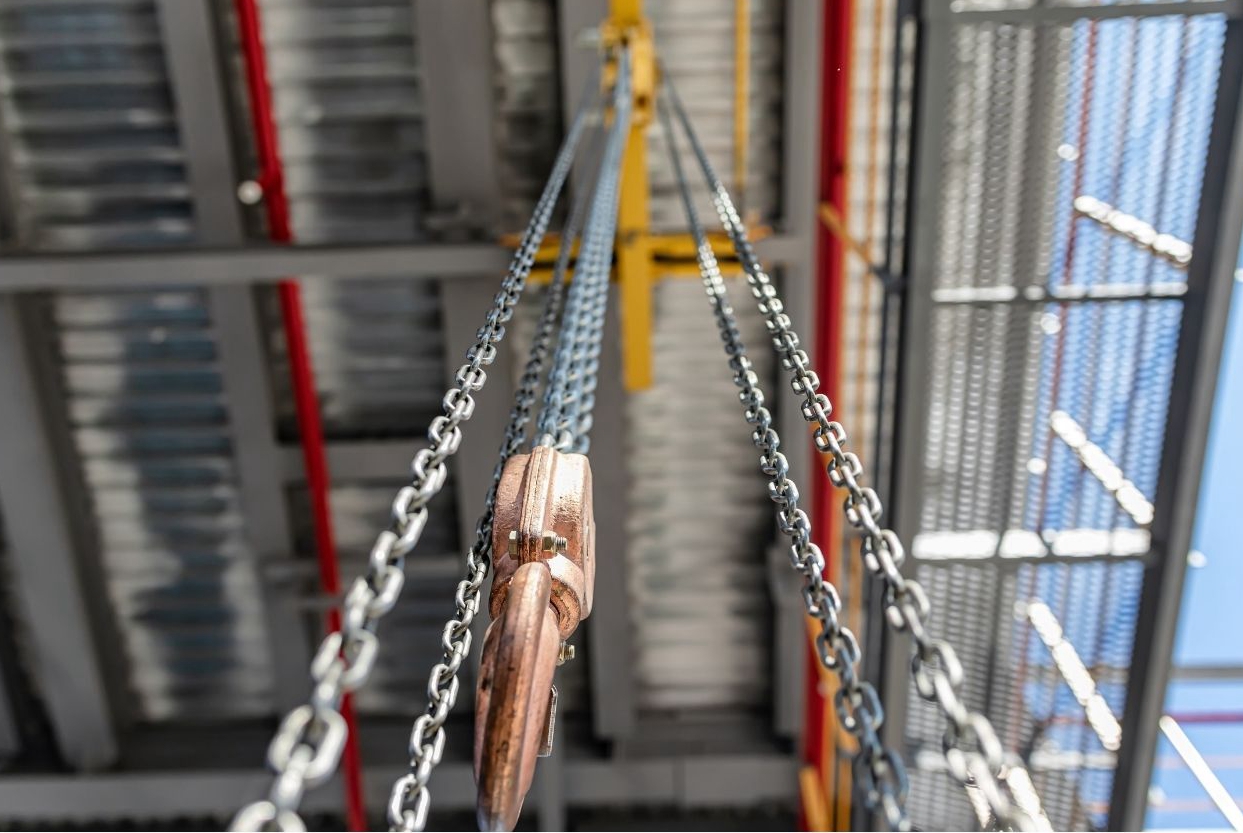

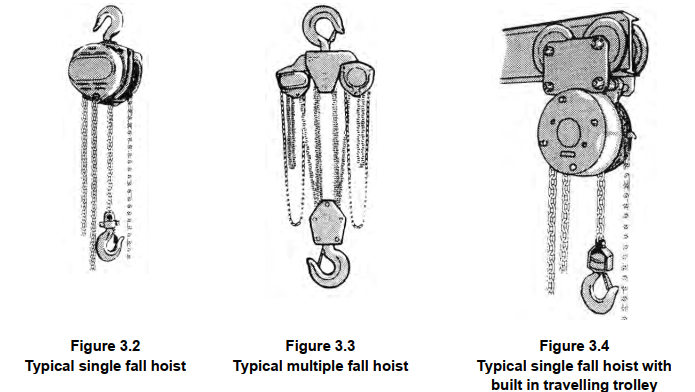

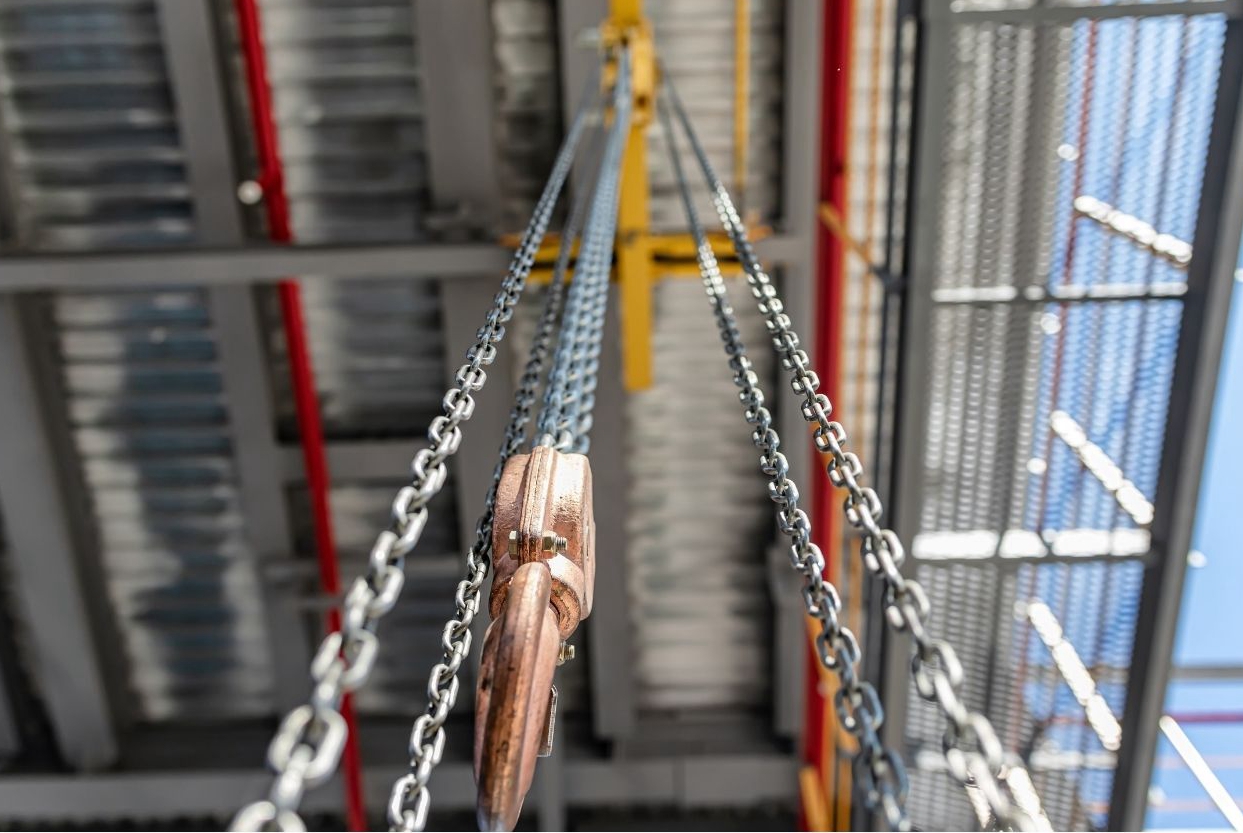

The hoist may be of ‘suspended’ or ‘combined’ unit, many manufacturers producing both options. Suspended types have a top hook, shackle, eyebolt or other fitting by which the hoist is hung and which allows a degree of articulation between the hoist and the supporting structure. (See figure 3.2) Combined types are usually combined with a purpose made travelling trolley, although a direct connection to the supporting structure may also be possible. (See figure 3.4) The connection between the hoist and the trolley or structure is usually rigid.

Number of Falls of Chain

The lower capacity hoists (e.g. 500kg, 1t) lift the load on a single fall of load chain. (See figures 3.2 and 3.4) Higher capacity hoists may either be of similar design but with a larger frame or may utilise two or more falls of load chain. The very high capacity hoists may utilise a combination of a larger frame and multiple falls of load chain and may even have two or more frames linked by a yoke. (See figure 3.3) The various configurations available each have their own advantages and disadvantages with regard to weight size, minimum drawn up dimension and cost.

Hand operated chain hoists are self-sustaining lifting mechanisms which provide an easy means of manually raising loads with acceptable operative effort. In the case of the larger capacities, they may be intended and arranged for more than one operative. Most chain hoists are designed for vertical lifting operations where the load is positioned directly below the hook although some are designed for use at an angle. They may be used in association with girder trolleys to move suspended loads along suitable tracks, e.g. runways.

The lower capacities are ideal for general use whilst the larger capacities are suitable for less frequent operations. Due to their comparative light weight and ease of installation, they are often used for temporary applications. They are also ideal for applications where no power source is available and are commonly used for maintenance purposes, in general workshops and storage areas where a lifting facility is required.

All modern hand operated chain hoists have a brake mechanism which makes them self-sustaining. However, some old types were not self-sustaining and these types are no longer considered suitable for use. Some national standards require hand operated chain hoists to have load limited devices fitted.

Method of Attachment

The hoist may be of ‘suspended’ or ‘combined’ unit, many manufacturers producing both options. Suspended types have a top hook, shackle, eyebolt or other fitting by which the hoist is hung and which allows a degree of articulation between the hoist and the supporting structure. (See figure 3.2) Combined types are usually combined with a purpose made travelling trolley, although a direct connection to the supporting structure may also be possible. (See figure 3.4) The connection between the hoist and the trolley or structure is usually rigid.

Number of Falls of Chain

The lower capacity hoists (e.g. 500kg, 1t) lift the load on a single fall of load chain. (See figures 3.2 and 3.4) Higher capacity hoists may either be of similar design but with a larger frame or may utilise two or more falls of load chain. The very high capacity hoists may utilise a combination of a larger frame and multiple falls of load chain and may even have two or more frames linked by a yoke. (See figure 3.3) The various configurations available each have their own advantages and disadvantages with regard to weight size, minimum drawn up dimension and cost.

Leave a Reply

Your email address will not be published.Required fields are marked. *