H-Lift Synthetic Bridle Roundsling features:

- Lightweight and easy to handle when compared to wire and chain bridles.

- Better load control and balance by using fixed connecting points and multiple legs

- Use of master links and hooks prevents cutting and abrasion of sling at bearing points.

- Pliable for easy storage.

- Standard: ASME/ANSI B30.9

- Safety factor 5:1

1-LEG SYNTHETIC BRIDLE SLING

| Item No. |

|

Color |

Rated Capacity |

Minimum Leg Length (ft) |

Product Code |

| Vertical (lbs) |

| RSBS-1-1 |

Purple |

2600 |

4 |

3100102600 |

| RSBS-1-2 |

Green |

5300 |

4 |

3100105300 |

| RSBS-1-3 |

Yellow |

8400 |

4 |

3100108400 |

| RSBS-1-4 |

Tan |

10600 |

4 |

3100110600 |

| RSBS-1-5 |

Red |

13200 |

4 |

3100113200 |

| RSBS-1-6 |

Wite |

16800 |

8 |

3100116800 |

| RSBS-1-7 |

Blue |

21200 |

8 |

3100121200 |

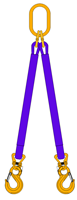

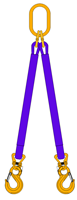

2-LEG SYNTHETIC BRIDLE SLING

| Item No. |

|

Color |

Capacity at Horizontal Angle (lbs) |

Product Code |

| 60o |

45o |

30o |

| RSBS-2-1 |

Purple |

4500 |

3700 |

2600 |

3100204500 |

| RSBS-2-2 |

Green |

9200 |

7500 |

5300 |

3100209200 |

| RSBS-2-3 |

Yellow |

14500 |

11800 |

8400 |

3100214500 |

| RSBS-2-4 |

Tan |

18300 |

14900 |

10600 |

3100218300 |

| RSBS-2-5 |

Red |

22800 |

18600 |

13200 |

3100222800 |

| RSBS-2-6 |

Wite |

29000 |

23700 |

16800 |

3100229000 |

| RSBS-2-7 |

Blue |

36700 |

29900 |

21200 |

3100236700 |

3-LEG SYNTHETIC BRIDLE SLING

| Item No. |

|

Color |

Capacity at Horizontal Angle (lbs) |

Product Code |

| 60o |

45o |

30o |

| RSBS-3-1 |

Purple |

6750 |

5520 |

3900 |

3100306750 |

| RSBS-3-2 |

Green |

13800 |

11250 |

7950 |

3100313800 |

| RSBS-3-3 |

Yellow |

21750 |

17700 |

12600 |

3100321750 |

| RSBS-3-4 |

Tan |

27450 |

22350 |

15900 |

3100327450 |

| RSBS-3-5 |

Red |

34200 |

27900 |

19800 |

3100334200 |

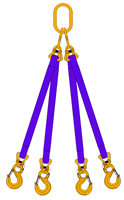

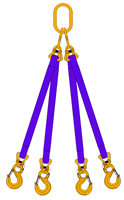

4-LEG SYNTHETIC BRIDLE SLING

| Item No. |

|

Color |

Capacity at Horizontal Angle (lbs) |

Product Code |

| 60o |

45o |

30o |

| RSBS-4-1 |

Purple |

9000 |

7360 |

5200 |

3100409000 |

| RSBS-4-2 |

Green |

18400 |

15000 |

10600 |

3100418400 |

| RSBS-4-3 |

Yellow |

29000 |

23600 |

16800 |

3100429000 |

| RSBS-4-4 |

Tan |

36600 |

29800 |

21200 |

3100436600 |

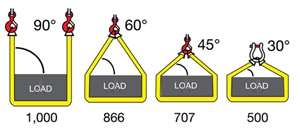

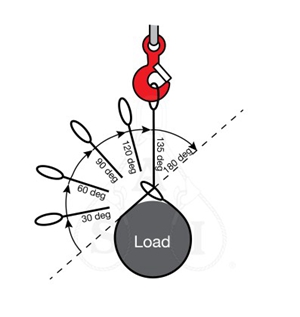

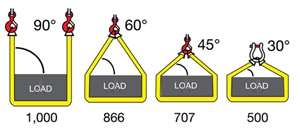

Horizontal angle or the sling angle is the angle where the sling meets the load. In the lifting and rigging industry, you want to make sure the angle is at least 30° or more.

Lifting and rigging specialists tend to prefer 60° angles. When a multi-leg sling is tagged, it is tagged for 60°. Slings also can be used at 45° or 30°, but for most of the lifts, 60° is the baseline sling angle that riggers want to use.

Sling Angle is the angle measured between the horizontal plane and the sling leg or body. When selecting a sling to carry a given load, it is important to consider the angle at which it is going to be used. The angle is very important and can have a dramatic effect on the rated capacity, due to the increase of tension caused by the angle.

As an example, one sling in a basket hitch or two slings attached to one crane hook are different applications involving different sling angles. The degree of the angle will determine how much the capacity will be reduced. To determine if a particular sling will have the capacity required, take the angle between the sling leg and the horizontal, then multiply the sling’s rating by the factor provided in the accompanying table.

In the example below, you will see how the 1,000lb capacity of a sling used in a vertical basket hitch is reduced taking these factors into consideration.

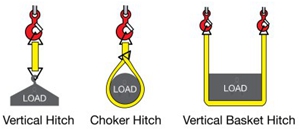

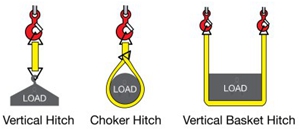

3 Basic Hitches

Effects of Sling Angles

Sling Capacity Changes as Angle Changes

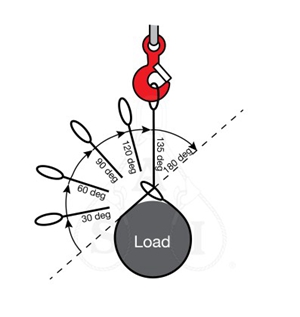

Sling Capacity and Choker Hitch Angles

Web Slings & Roundslings – WSTDA

Angle of Choke (Degrees)

Equal to or greater than |

Angle of Choke (Degrees)

Less than |

Reduction Factor |

| 120 |

180 |

1 |

| 105 |

120 |

.82 |

| 90 |

105 |

.71 |

| 60 |

90 |

.58 |

| 0 |

60 |

.50 |

Choker Hitch Capacity x Reduction Factor = Reduced Choker Hitch Capacity