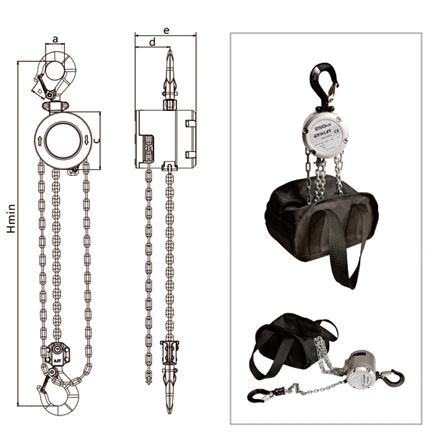

H-Lift Chain Block/Chain Hoist

ALWAYS:

• Store and handle chain hoists correctly.

• Inspect chain hoists and accessories before use and before placing into storage.

• For top hook suspension, use hooks that are fitted with safety catches, or mouse the hook, ensuring the support fits freely into the seat of the hook.

• For trolley suspension ensure the trolley is correctly set for the beam width.

• Check that the bottom hook will reach its lowest point without running the chain fully out.

• Adopt safe slinging practices and follow the instructions for the safe use of the equipment used.

NEVER:

• Expose chain hoists to chemicals, particularly acids, without consulting the supplier.

• Replace the load chain with a longer one without consulting the supplier.

• Use undue effort to force the hoist to operate.

• Throw, drop or drag a chain hoist.

• Allow oil or grease to come into contact with the brake.

• Expose a chain hoist directly to the elements, water spray, steam etc without consulting the supplier.

Selecting the Correct Hoist

Hand chain hoists are available in a range of capacities and with various types of suspension. Select the hoist to be used and plan the lift taking the following into account:

Type of suspension - hook, trolley etc.

Capacity, class of use and range of lift.

Chain hoists are designed for vertical lifting only.

Consult the supplier if the hoist is to be used in areas of high risk, exposed to the elements, water, steam etc, with hazardous substances, e.g. acids or chemicals, or subjected to extremes of temperature.

Storing and Handling Hand Chain Hoists

Never return damaged hoists to storage. They should be dry, clean and protected from corrosion.

Store hoists by their top suspension with chains clear of the ground, the chains may be wrapped together to facilitate this. Non-portable hoists stored outdoors should be covered and protected from corrosion.

Hoists should not be dropped, thrown or dragged across the floor.

Never galvanise or subject the chain, or other load bearing parts, to any other plating process without the express approval of the supplier.

Installing and Commissioning

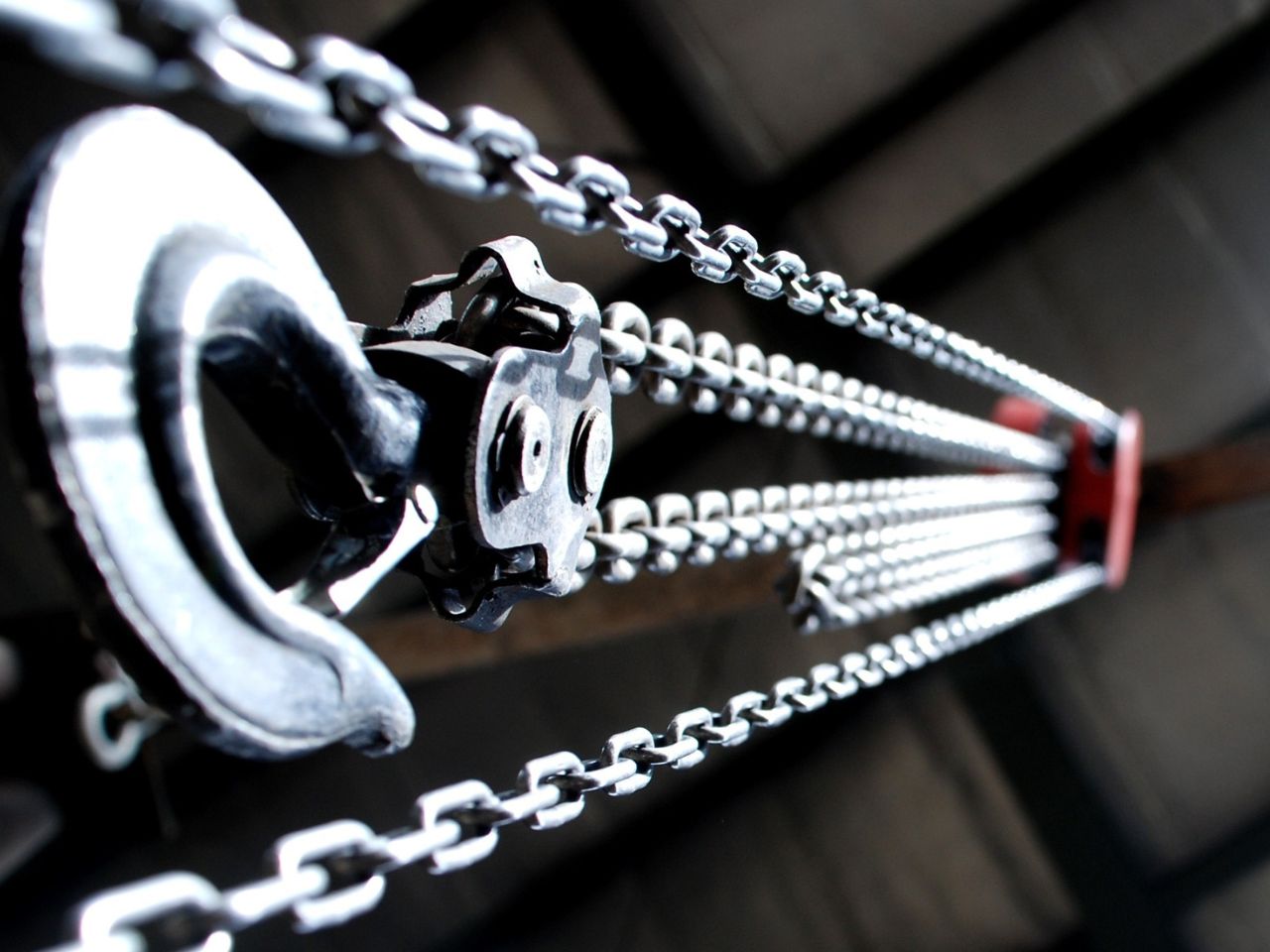

Follow any specific installation instructions issued by the supplier and the general requirements given overleaf. Try the hoist to ensure that it operates correctly and that the brake is effective. Ensure the chain is not twisted; it must move freely. The bottom hook must reach the lowest position required without the chain running fully out.

Using Hand Chain Hoists Safely

Do not attempt lifting operations unless you understand the use of the equipment and the slinging procedures.

Do not use defective hoists, slings or accessories and never use the chain hoist as a sling.

Check the slinging arrangement, that the hoist is safely rigged and that chains are not twisted, particularly in the case of multi-fall hoists.

Check the load is free to move before commencing and that the landing area has been prepared.

Raise the load just clear, then halt the lift to check the integrity of the hoist, slinging method etc.

Check the travel path is clear and that you have a clear view so as to avoid accidental hook engagement or collision. Follow any particular site safety rules applicable to the movement of suspended loads.

Keep fingers, toes etc clear when lowering loads.

In-service Inspection and Maintenance

Follow any specific maintenance instructions issued by the supplier but in particular keep load chains lubricated and check the operation of the brake. Brakes must be kept free of oil, grease etc. Never replace the load chain with a longer one without consulting the supplier.

Regularly inspect the hoist and, in the event of the following defects, refer the hoist to a Competent Person for thorough examination: wear; damage to trolley, hooks and fittings; damaged or distorted slack end anchor; chains worn, bent, notched, stretched, corroded, do not hang freely, twisted orjump; load slips or will not lift; damaged hoist casing; illegible markings.