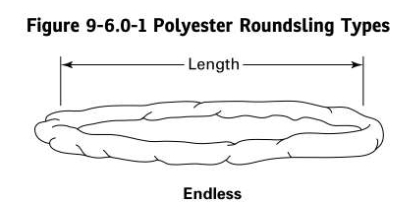

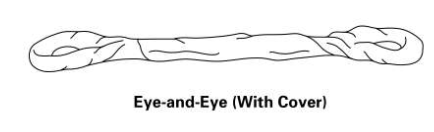

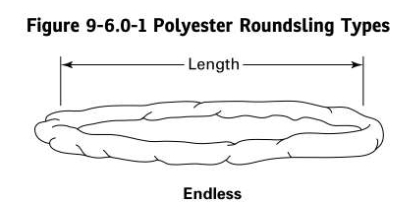

Polyester round slings, also known as endless slings or round slings, are versatile and flexible lifting slings made from high-strength polyester fibers. They are commonly used in various lifting and rigging applications due to their durability, ease of use, and ability to conform to the shape of the load being lifted. Here are some key characteristics and benefits of polyester round slings:

1. Construction: Polyester round slings are typically constructed from a continuous loop of polyester webbing that is stitched together. The load-bearing fibers are protected by an outer polyester jacket, which provides additional abrasion resistance and protection.2. Strength and Load Capacity: These slings are designed to have high tensile strength and load-bearing capacity. They come in various load capacity ratings, ranging from a few hundred pounds to several tons, making them suitable for a wide range of lifting tasks.3. Flexibility: The design of round slings allows them to easily conform to the shape of the load, which can be especially useful when lifting irregularly shaped objects or machinery.4. Lightweight: Polyester round slings are relatively lightweight compared to some other types of lifting slings, making them easy to handle and transport.5. Safety: They are color-coded to indicate their load capacity, which helps users select the appropriate sling for the job. Additionally, they are less likely to cause damage to the load compared to some other types of slings.6. Versatility: Polyester round slings are suitable for a wide range of lifting applications, including vertical, choker, and basket hitches. They are commonly used in industries such as construction, manufacturing, material handling, and more.7. Durability: These slings are resistant to moisture, UV radiation, and many chemicals, making them suitable for outdoor and challenging environments.8. Easy Inspection: Polyester round slings are easy to inspect for signs of wear, damage, or other issues that may affect their safety. Regular inspections are essential to ensure their reliability.9. Longevity: With proper care and maintenance, polyester round slings can have a long service life, making them cost-effective over time.10. Storage and Handling: When not in use, round slings should be stored properly to prevent damage or contamination. They should be protected from sharp objects and stored away from direct sunlight.

It's important to follow manufacturer instructions and industry standards, such as ASME B30.9 or other relevant guidelines, when using polyester round slings to ensure safe lifting operations. Regular inspections and maintenance are crucial to identifying and addressing any issues that may compromise the integrity of the slings.