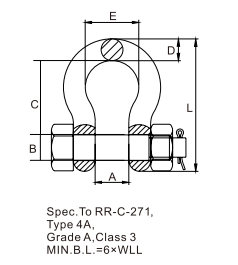

Anchor Shackle and Chain Shackle

ALWAYS:

• Store and handle shackles correctly.

• Inspect shackles before use and before placing into storage.

• Select the correct pattern of shackle and pin for the application.

• Allow for the full resultant imposed load.

• Fully tighten the pin.

• Ensure the load acts through the centre line of the shackle using spacers if necessary to meet this requirement.

NEVER:

• Use shackles with bent pins or deformed bodies.

• Force, hammer or wedge shackles into position.

• Eccentrically load shackles.

• Replace the pin with a bolt.

• Fit pins in contact with moving parts which may loosen or unscrew them.

• Shock load shackles.

Selecting the Correct Shackle

Shackles are available in a range of material grades, sizes and designs. Select the shackle to be used and plan the lift taking the following into account:

Type of shackle to be used - dee or bow, British Standard or other design.

Type of pin - screwed with collar and eye are suitable for general purposes; with countersunk head for where clearance is limited; bolt and nut for where the pin may be out of sight or subject to movement.

Full resultant imposed load - when using shackles with multi-leg slings remember that as the included angle increases and so does the load in the leg and any attachment to the leg. When used to suspend pulley blocks account must be taken of the imposed load due to operating effort.

CAUTION: BS and ISO Standard shackles are designed and rated for the pin to accept a central point load. Other, commonly available, types are designed and rated for the load to be evenly distributed over the full width of the pin. Unless the basis for rating is clearly stated it should be assumed that the jaw must be fully filled and the load evenly spread across the shackle pin width.

Storing and Handling Shackles

Never return damaged shackles to storage. They should be dry, clean and protected from corrosion.

Do not alter, modify or repair shackles and never replace missing pins with unidentified pins, bolts etc, but refer such matters to a Competent Person.

Never galvanise or subject a shackle to other plating processes without the approval of the supplier.

Using Shackles Safely

Do not attempt lifting operations unless you understand the use of the equipment, the slinging procedures and the mode factors to be applied.

Do not use defective shackles or unidentified pins.

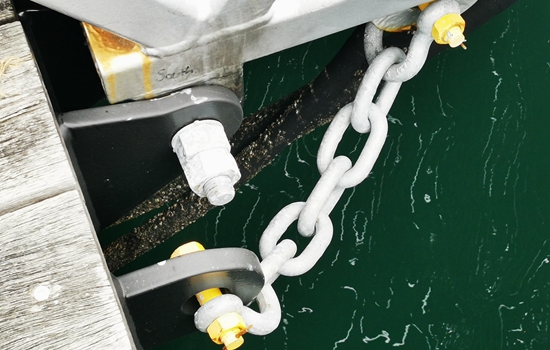

Shackles should be fitted so that the body takes the load along its centre line and is not subjected to side bending loads. When connecting a number of sling legs, and similar applications, position them so that they do not impose a side load on the shackle jaws. Use spacers to position them if necessary.

Ensure the pin is correctly screwed into the shackle eye. Tighten by hand, use a small bar to lock the collar to the shackle eye. Check that the thread is fully engaged with the body but is not too long so that tightening causes the body to deform.

With bolt and nut pins ensure the nut jams on the inner end of the thread and not on the eye of the shackle. The bolt should be free to rotate with minimal side float. The split cotter pin must be fitted before making a lift.

When using shackles with slings in choke hitch, or in other applications where there may be movement, place the pin through the eye or link of the sling and never in contact with the bight of the choke or moving parts which may cause the pin to unscrew.

In-service Inspection and Maintenance

Maintenance requirements are minimal. Keep shackles clean, the threads free of debris and protect from corrosion.

Regularly inspect shackles and, in the event of the following defects, refer the shackle to a Competent Person for thorough examination: illegible markings; distorted, worn, stretched or bent body; bent pin; damaged or incomplete thread forms; nicks, gouges, cracks or corrosion; incorrect pin; any other defect.