Blue E-coating (electrophoretic coating) on Grade 100 chain is a type of corrosion-resistant finish applied to the chain's surface. It provides several advantages, including enhanced protection against rust and corrosion, improved aesthetics, and increased durability. Here are some key points about blue E-coating on Grade 100 chains:

- Corrosion Resistance: Blue E-coating creates a protective layer on the chain's surface, making it highly resistant to corrosion. This is particularly important for chains used in outdoor or harsh environments where exposure to moisture and corrosive substances is a concern.

- Aesthetics: The blue E-coating not only serves a functional purpose but also provides an attractive finish to the chain. This can be beneficial in applications where appearance matters.

- Durability: The E-coating process involves applying a uniform and consistent layer of coating, ensuring that the chain is thoroughly protected. This can extend the chain's service life and reduce the need for frequent replacement.

- Color Coding: The blue color of the E-coating can serve as a visual indicator, making it easier to identify Grade 100 chains in a workspace or when performing inspections. Color coding can help ensure that the correct chain is used for specific applications.

- Application: Chains with blue E-coating are commonly used in heavy-duty lifting and rigging applications, especially in industries like construction, mining, and offshore operations where corrosion resistance and strength are critical.

- Maintenance: While E-coating provides excellent corrosion resistance, it's still essential to perform regular inspections and maintenance on Grade 100 chains, especially if they are exposed to harsh conditions or subjected to heavy loads.

When selecting Grade 100 chains with blue E-coating, it's important to verify that the coating meets industry standards and specifications. Additionally, always follow the manufacturer's guidelines for proper usage, maintenance, and inspection to ensure the safety and reliability of the chain in your specific application.

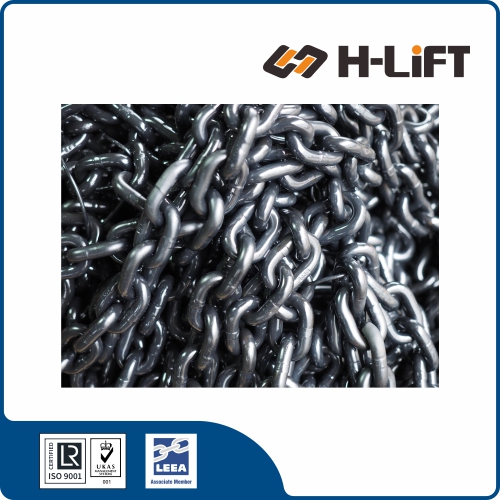

Below is a picture of lifting chain with blue e-coating and black e-coating for your reference.