Grade 100 sling components are high-strength lifting and rigging components designed for heavy-duty lifting applications. These components are typically used in combination to create robust and reliable lifting slings. Grade 100 refers to the material strength and load-bearing capacity of these components. Here are some common Grade 100 sling components:

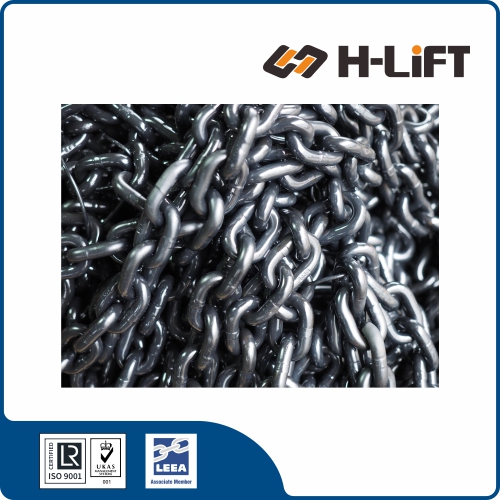

- Grade 100 Chain: Grade 100 chains are the primary load-bearing element in many lifting slings. They are designed to have a working load limit (WLL) that is 25% of their minimum break strength (MBS), making them suitable for lifting heavy loads.

- Master Links: Grade 100 master links are used to connect chains and other components within the sling assembly. They are often the central attachment point for the load.

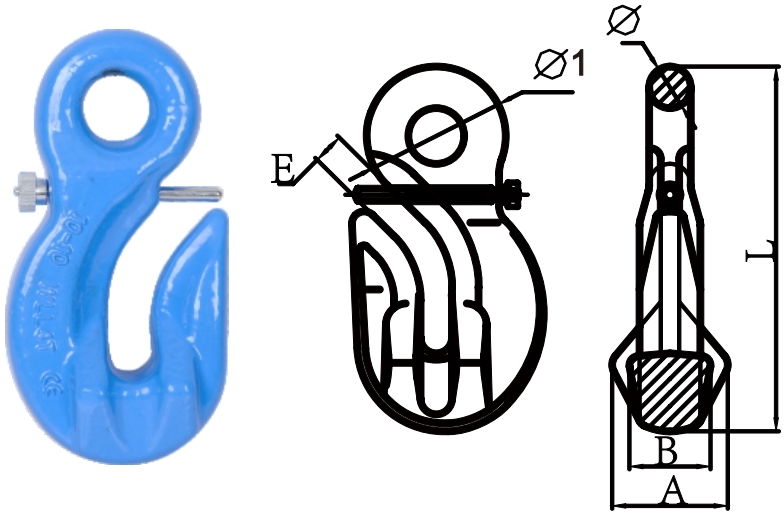

- Hooks: Grade 100 hooks are essential for connecting the sling to the load or anchor point. They come in various styles, including clevis hooks, grab hooks, and eye hooks, to suit different applications.

- Chain Slings: Chain slings are assemblies made from Grade 100 chain, master links, and hooks. They come in different configurations, such as single-leg, double-leg, and multiple-leg slings, depending on the lifting requirements.

- Shortening Clutches: Shortening clutches are used to adjust the length of chain slings, allowing for better load positioning and balance.

- Connecting Links: Grade 100 connecting links are used to connect different sling components or to create adjustable sling configurations.

- Sling Tags: These tags provide important information about the sling's specifications, including its working load limit, material grade, and inspection guidelines.

- Load Binders: Grade 100 load binders are used to secure and tension chains for load restraint applications, such as securing cargo on trucks and trailers.

- Chain and Hook Accessories: Accessories like chain protectors, latch kits, and safety pins are used to enhance the safety and usability of Grade 100 chains and hooks.

Grade 100 sling components are known for their exceptional strength and durability. When using them in lifting applications, it's crucial to follow safety guidelines, perform regular inspections, and adhere to industry standards. Proper maintenance and usage are essential to ensure the safety and reliability of the lifting sling and to prevent accidents or injuries during lifting operations.