A lever type load binder is a mechanical device used to secure cargo or loads on trucks, trailers, or other transportation vehicles. It is also known as a lever binder, cargo binder, or load tensioner.

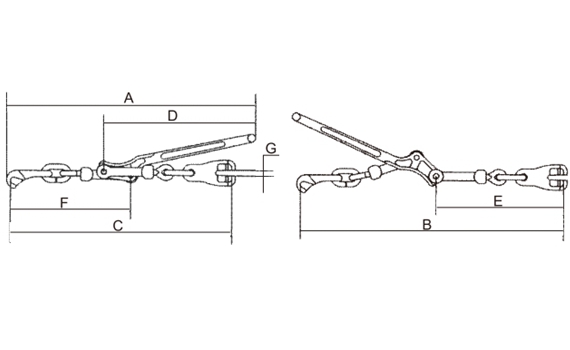

The lever binder consists of a lever and a chain with hooks on each end. One end of the chain is connected to the anchor point on the truck or trailer, while the other end is connected to the load. The lever is used to tighten the binder, creating tension on the load and securing it in place.

The advantage of using a lever binder is that it is easier to use and requires less physical effort than a ratchet binder. However, it is less precise in terms of tension control and adjustment.

It is important to use the lever binder properly to avoid over-tightening and damaging the load or the equipment. It is also important to inspect the binder regularly for signs of wear or damage and to replace it if necessary.

ALWAYS:

• Inspect chain lashings before use.

• Calculate the lashing force(s) required for the chosen method of load restraint.

• Select the capacity and number of chain lashings to provide at least the calculated lashing force(s)

• Ensure the lashing points on the vehicle and/or load are of adequate strength.

• Protect the chain lashing from small radii edges or reduce the lashing capacity in accordance with the manufacturer’s instructions.

• Ensure the chain lashings are correctly tensioned.

• Exercise care when releasing chain lashings in case the load has become unstable since the lashings were applied.

NEVER:

• Use chain lashings to lift a load.

• Knot, tie or modify chain lashings.

• Overload chain lashings.

• Use chain lashings over a sharp edge without edge protection or reducing the lashing capacity.

• Expose chain lashings to chemicals without consulting the supplier.

• Use chain lashings which have any distorted chain links, a damaged tensioner, damaged terminal fittings or a missing ID tag.

Selecting the Correct Chain Lashing

The standard for chain lashings is BS EN 12195-3: 2001. It requires the chain to conform to EN 818-2 and the connecting components to conform to EN 1677-1, 2 or 4 as appropriate. Connecting and shortening components must have a have a securing device such as a safety latch.

These standards are for grade 8 items. Some manufacturers also offer higher grades which, size for size, have a greater lashing capacity.

Chain lashings are available in a range of capacities and lengths and in various configurations. Some are general

purpose. Others are intended for specific applications.

Selection should start with an assessment of the forces acting on the load. The lashing force(s) required should be calculated in accordance with BS EN 12195-1: 2010.

Next check whether the lashing points on the vehicle and/or load are of adequate strength. If necessary apply a greater number of lashings to spread the force across more lashing points.

Chain lashings are marked with their lashing capacity (LC). expressed in daN (deca Newton = 10 Newtons) This is a force approximately equivalent to a weight of 1kg.

Using Chain Lashings Safely

Ensure that the tensioner is free to align and not bent over an edge. Ensure that the chain is not twisted or knotted and that the terminal fittings engage correctly with the lashing points.

For two part lashings, ensure the parts are compatible.

Ensure that the chain is protected from sharp and small radius edges by suitable packing or edge protectors.

Note: The manufacturer’s instructions may permit use over small radius edges provided the lashing capacity is reduced.

In-service Inspection and Storage

Chain lashings can be damaged by tensioning the chain across small radius edges without adequate edge protection. However damage may occur accidentally as a result of the load moving in transit hence the need to inspect before each use.

Chain lashings should not be exposed to chemicals, particularly acids which can cause hydrogen embrittlement. If accidental contamination occurs, the lashings should be cleaned with clear water and allowed to dry naturally. Weak chemical solutions will become increasingly stronger by evaporation.

Chain lashings should be inspected for obvious signs of damage before each use. Do not use the chain lashing if any of the following defects are found: illegible markings; bent, elongated or notched chain links, distorted or notched coupling components or end fittings, ineffective or missing safety latches.

Chain lashings will gradually wear over time. The LEEA recommends that they should be inspected by a competent

person at least every 6 months and a record made of the result.

Chain lashings should only be repaired by someone competent to do so.

For long term storage the storage area should be dry, clean and free of any contaminates.