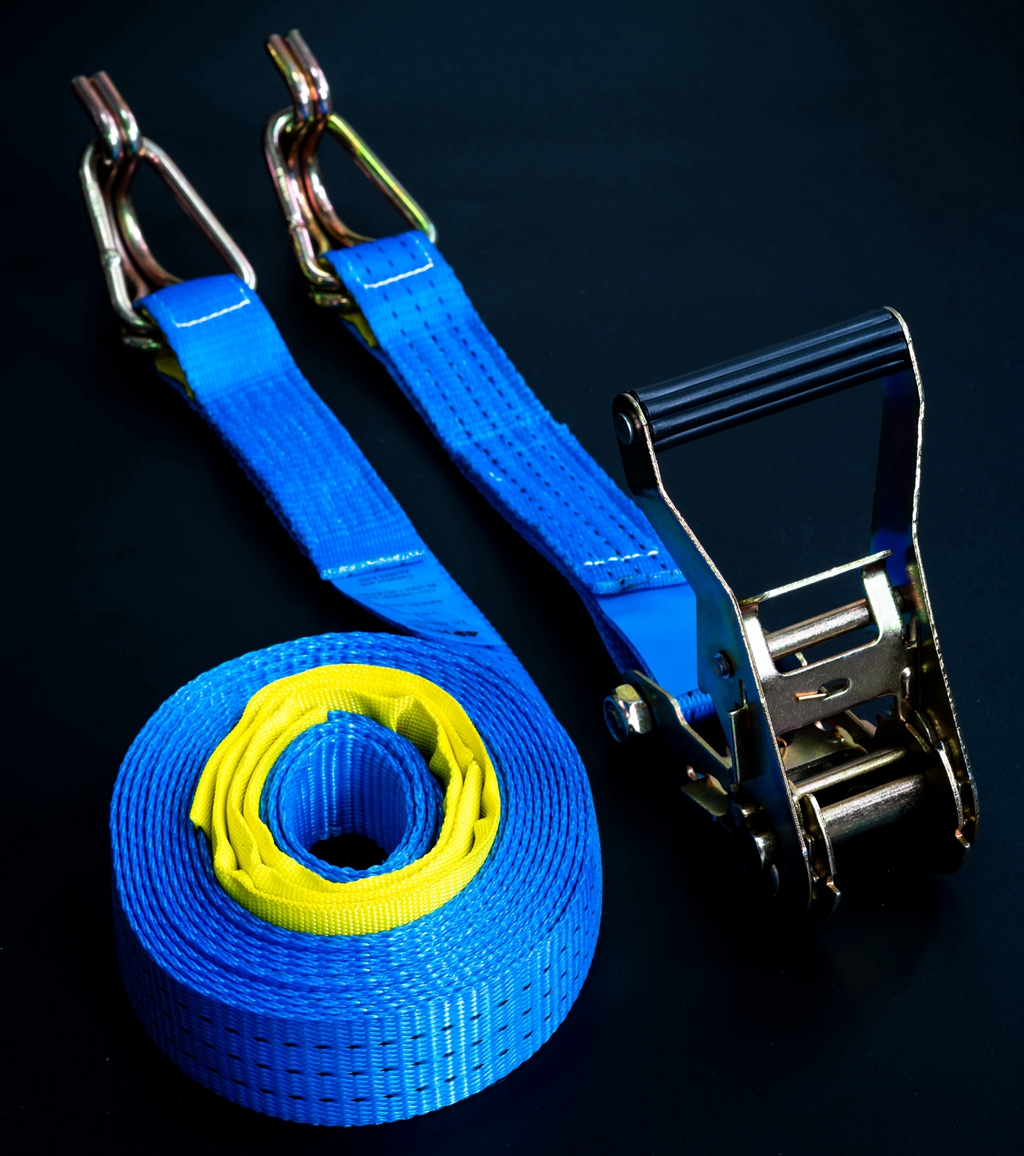

Ratchet Tie-down Lashing System

ALWAYS:

• Inspect ratchet tie downs before use.

• Calculate the lashing force(s) required for the chosen method of load restraint.

• Select the capacity and number of ratchet tie downs to provide at least the calculated lashing force(s)

• Ensure the lashing points on the vehicle and/or load are of adequate strength.

• Position the ratchet tie down so that the load is uniformly spread over its width and protect the ratchet tie down from small radii, especially sharp edges.

• Ensure the ratchet tie downs are correctly tensioned.

• Exercise care when releasing ratchet tie downs in case the load has become unstable since the lashings were applied.

NEVER:

• Use ratchet tie downs to lift a load.

• Knot or tie ratchet tie downs.

• Overload ratchet tie downs.

• Use ratchet tie downs over a sharp edge without edge protection.

• Expose ratchet tie downs to direct heat or flames.

• Expose ratchet tie downs to chemicals without consulting the supplier.

• Use ratchet tie downs which are cut, have loose or damaged stitching, a damaged tensioner or damaged terminal fittings.

Selecting the Correct Ratchet Tie Down

The standard for ratchet tie downs is AS/NZS 4380.

Ratchet tie downs are available in a range of capacities and lengths and in various configurations. Some are general purpose. Others are intended for specific applications such as securing cars by their wheels.

Selection should start with an assessment of the forces acting on the load. The lashing force(s) required should be calculated in accordance with AS/NZS 4380.

Next check whether the lashing points on the vehicle and/or load are of adequate strength. If necessary apply a greater number of lashings to spread the force across more lashing points.

Ratchet tie downs are marked with their lashing capacity (LC). expressed in kg.

Using Ratchet Tie Downs Safely

Ensure that the tensioner is free to align and not bent over an edge. Ensure that the webbing is not twisted or knotted and that the terminal fittings engage correctly with the lashing points.

Ensure that the webbing is loaded evenly across its width and protected from sharp and small radius edges by suitable sleeves or edge protectors

Checking the tension after travelling a short distance is recommended.

Ensure that the webbing is protected against sources of friction, abrasion and heat.

In-service Inspection and Storage

Ratchet tie downs can easily be damaged by tensioning the webbing across small radius edges or loading the edge of the webbing instead of ensuring the load is spread over its full width. Avoid this by correct placement of the ratchet tie down and the use of protective sleeves and edge protection. However damage may occur accidentally as a result of the load moving in transit hence the need to inspect before each use. Ratchet tie downs may accidentally be exposed to chemicals. Most are manufactured from polyester which is resistant to moderate strength acids but is damaged by alkalis. Weak chemical solutions will become increasingly stronger by evaporation. If appropriate, the webbing may be cleaned with clear water and allowed to dry naturally. Never force dry ratchet tie downs.

Ratchet tie downs should be inspected for obvious signs of damage before each use. Do not use the ratchet tie down if any of the following defects are found: illegible markings; damaged, chaffed or cut webbing; damaged or loose stitching; heat damage; burns; chemical damage; solar degradation; damaged or deformed end fittings.

Ratchet tie downs will deteriorate gradually over time due to normal wear. We recommends that they should be inspected by a competent person at least every 6 months and a record made of the result.

Ratchet tie downs should only be repaired by someone competent to do so.

For long term storage the storage area should be dry, clean, free of any contaminates and shaded from direct sunlight.