A Complete Guide to Wire Rope Clips

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. Whether for use on cranes or for other lifting applications, it’s important to have a solid understanding of the rigging components that are being used to attach to and lift a load.

As a rigger or end-user of wire rope, it’s necessary to understand the types of wire rope end termination, or treatments that can be used at the ends of a length of wire rope—one of the most common being wire rope clips.

What is a Wire Rope Clip?

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

As a general guideline, they are NOT to be used for making slings, as ASME B30.9 Slings standard states: “Mechanical wire rope terminations requiring periodic adjustment to maintain efficiency shall not be used to fabricate slings.”

Examples of situations where a wire rope clip could be utilized include:

Wire rope end termination on a crane cable or winch

To run a length of wire rope through an eye bolt or shackle

Perimeter cables on docks, parking lots, etc.

Types of Wire Rope Clips

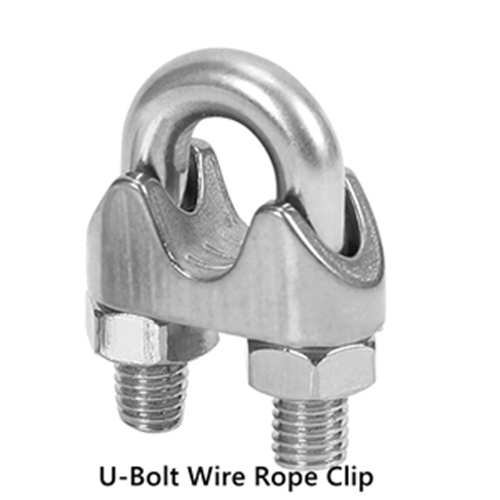

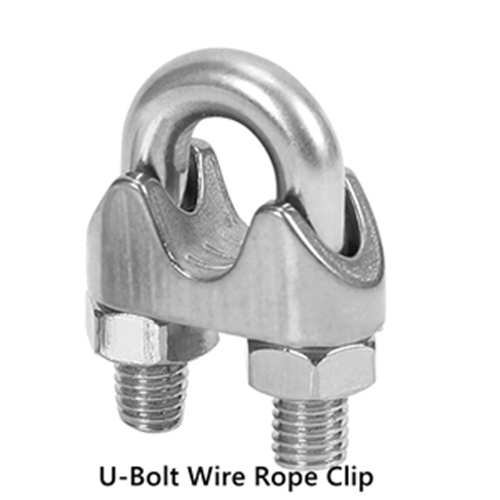

There are two main types of wire rope clips—U-Bolt wire rope clip and double saddle wire rope clips. U-Bolt wire rope clips are the most common and may be made of forged or malleable metal.

U-Bolt Wire Rope Clips

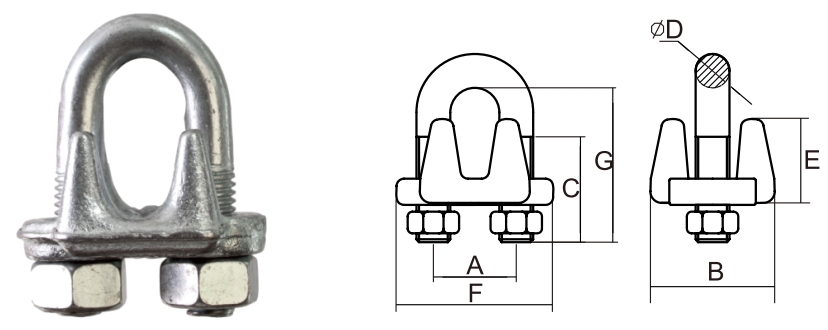

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

Forged Wire Rope Clips

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable Wire Rope Clips

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

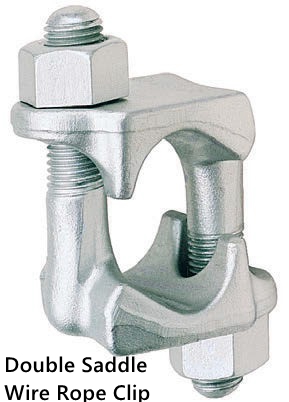

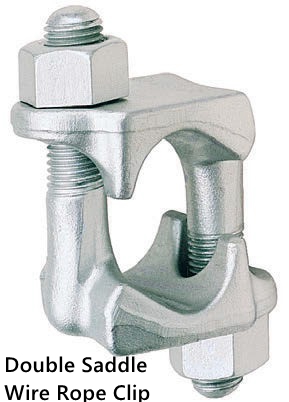

Double Saddle Wire Rope Clips

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

Overhead lifting vs. sustaining overhead loads

The ‘overhead lifting’ versus ‘sustaining overhead loads’ can be confusing, but a good rule of thumb to ask is: “Is the object being moved or being held in place?” If it is being moved, then wire rope clips are not to be used. If it is being held in place, then the next question is: Is it above ground (suspended from the ceiling, an awning, scaffolding, etc…) or will it be on a fence or on another object near the ground? If it is above ground, heavy-duty drop-forged is the best choice. If on a fence near the ground, malleable clips are acceptable.

It’s important to note that wire rope clips diminish the working load limit of the wire rope to generally about 80% of its original strength.

Common Mistakes When Installing Wire Rope Clips

Unfortunately, it is not uncommon to see a wire rope clip applied incorrectly. Some of the most common mistakes include:

Not torquing to the manufacturer’s expectations

Not using the recommended number of clips

Incorrect spacing between clips

Saddle is on the incorrect end of the rope

Incorrect amount of turnback when forming an eye

Using the wrong type of clip for the application

Not matching the clip size to the wire rope size

Failing to cycle the rope and regularly tighten the clips

Wire rope clips require the use of a torque wrench in order to function properly. Torquing the nuts on the clips too much or too little can cause the clip to fail. If the clip is over-torqued, it could damage the threads of the wire rope. If the clip is under-torqued, the holding power of the clip is diminished and the wire rope could slip through.

Not Using the Recommended Number of Clips

There are a minimum number of clips required for use related to the wire rope diameter. Using less than the number of specified clips could result in decreased efficiency and possible failure.

Incorrect Spacing Between Clips

Depending on the number and size of the wire rope clips, there is a proportional amount of space required between the placement on each clip on the rope.

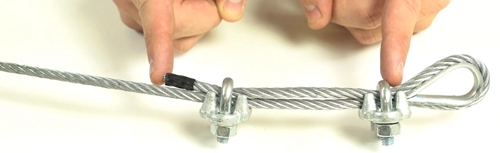

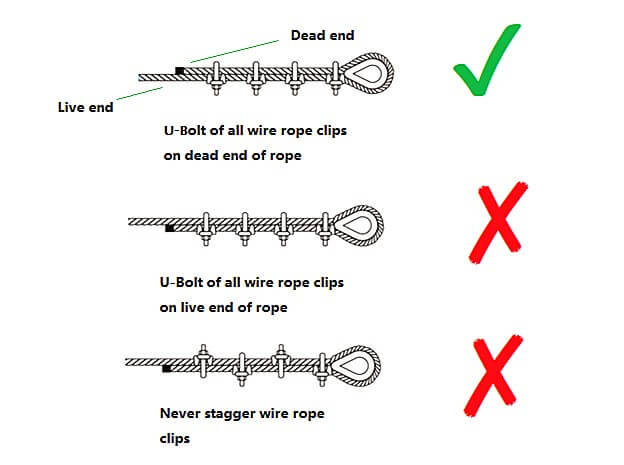

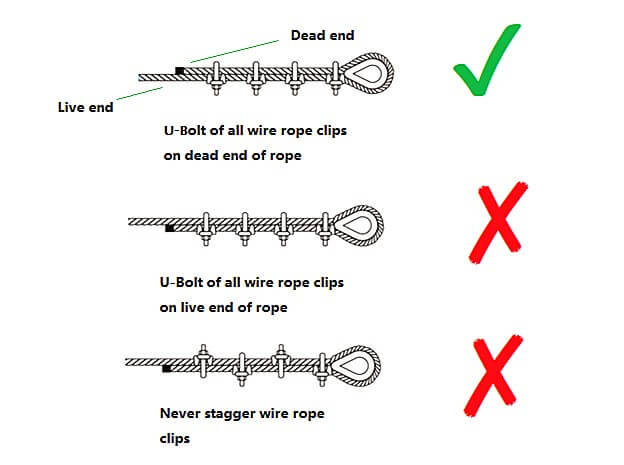

Saddle is on the Incorrect End of the Rope

There are two sides of a U-Bolt style wire rope clip: the saddle and the U-Bolt. When securing a wire rope eye, it is important to place the clip on the correct end of the rope. The saddle of the clip rests on the live end of the rope, while the U-bolt is to rest on the dead end of the rope.

A saying commonly used in rigging to help remember this is: “Never saddle a dead horse!” In other words, never put the saddle on the dead end of the rope.

Incorrect Amount of Turnback When Forming an Eye

The turnback is the portion of the wire rope eye that runs from the end of the bearing eye to the live end. Having less than the suggested amount of turnback will decrease the efficiency of the wire rope eye and could lead to failure.

Using the Wrong Type of Clip for the Application

It is important to be sure you are using the correct wire rope clip—forged or malleable wire rope clips—for the application. Malleable clips can only be used for non-critical uses, such as tension rope to form a perimeter around a parking lot.

If the use is critical—an application where, if there is a failure, you have potential injury or loss of life or damage to property—a forged clip must be used.

Not Matching the Clip Size to the Wire Rope Size

The clip size used—whether it be 1/8”, 3”, or otherwise—must match the diameter size of the wire rope. If it doesn’t, the wire rope could slip out of the clip.

Failing to Cycle the Rope and Regularly Retighten the Clips

After installing clips, it is necessary to regularly cycle the rope and retighten the clips. Monitoring the torque on the nuts is important, as they will loosen over repeated use.

How to Install a Wire Rope Clip on an Eye or Thimble

The proper way to use wire rope clips can be remembered this way: “Never saddle a dead horse.” The saddle of the clip is the piece that fits into the U bolt. The dead-end of a wire rope is the end of the eye that contains the cut side. The U bolt should always be in contact with the dead-end, while the saddle should be on the live end.

Basic steps for installing a wire rope clip include:

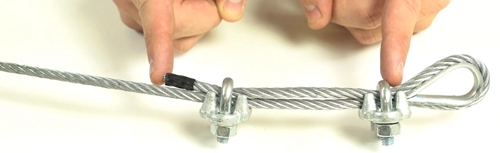

First, wrap the wire rope around the thimble or to form the eye, and turn back the correct amount of rope—as specified by the manufacturer.

Apply the first wire rope clip at the end of the dead end, with one base width of space. Use a torque wrench to tighten the nuts on the wire rope clip.

When applying the second clip (if required), place it as close to the eye loop or thimble as possible. Again, be sure to properly tighten the nuts of the clip with a torque wrench.

If more than two clips are required, the clips should be evenly spaced between the two that were placed first.

Wrapping it Up

Wire rope clips are a common and necessary piece of rigging hardware when it comes to using wire rope and forming end terminations. They are used to form a wire rope eye or to connect two cables together. It’s important to understand how to correctly install a wire rope clip, as incorrect installation leads to decreased efficiency in the wire rope assembly.

The main types of wire rope clips are:

U-Bolt wire rope clips

Forged

Malleable

Double saddle wire rope clips

Some of the most common mistakes when using wire rope clips are:

Not torquing to the manufacturer’s expectations

Not using the recommended number of clips

Incorrect spacing between clips

Saddle is on the incorrect end of the rope

Incorrect amount of turnback when forming an eye

Using the wrong type of clip for the application

Not matching the clip size to the wire rope size

Failing to cycle the rope and regularly tighten the clips