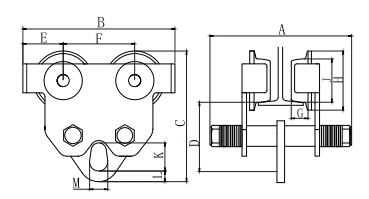

H-Lift Push and Geared Tavel Trolley

A push and gear travel trolley is a device used to move heavy loads along an I-beam or other similar track. It consists of a trolley frame, wheels or rollers, and a suspension system for attaching the load.

The plain trolley is recommended where trolley motion is infrequent or relatively short. Due to the required forece to manually operate this type of trolley, it is also recommened that the plain trolleys be limited to a maximum of 3 tons(3000kg) capacity with the elevation of the beam not more than 20 feet (6m) above the operator's floor level.

The hand chain pull geared trolley is recommended where trolley motion is relatively infrequent or short, and for those loads and beam heights where a plain type trolley would be impractical. The hand chain operated trolley provides good load spotting ability.

The trolley motion is obtained by pulling on the hand chain, which rotates a hand chain wheel, which in turns is directly connected to the trolley wheels through gears or sprockets. Hand chain operated trolleys are recomended for

(a) capacities over 3 tons (3000kg)

(b) beam elevations greater than 20 feet (6 m) above operator's floor level.

(c) accurate load spotting ability

The trolley can be manually pushed along the track or equipped with a gear system for easier movement of heavier loads. The gear system allows the operator to turn a hand crank or use an electric motor to move the trolley along the track.

Push and gear travel trolleys are commonly used in industries such as manufacturing, construction, and warehousing to move heavy objects such as machinery, equipment, and materials. They are especially useful in areas where overhead cranes are not feasible or practical.

To use a push and gear travel trolley, the trolley is attached to the load using a suspension system such as chains or straps. The trolley is then placed on the track and moved along the track manually or with the use of the gear system. The trolley can be stopped and started as needed to position the load or transport it to a different location.

Push and gear travel trolleys come in a variety of sizes and weight capacities to suit different applications. Some models are equipped with additional features such as adjustable widths and anti-derailment devices for added safety and stability.

ALWAYS:

• Store and handle trolleys correctly.

• Inspect trolleys, blocks and accessories before use and before placing into storage.

• Ensure the wheel profile is suitable for the track.

• Check the trolley width is correctly set for the track.

• Ensure the track is fitted with positive end stops.

• Push rather than pull loads suspended on push/pull trolleys.

NEVER:

• Expose trolleys to chemicals, particularly acids, without consulting the supplier.

• Force or wedge the suspension hook of blocks onto the load bar.

• Throw or drop a trolley.

• Expose a trolley directly to the elements, water spray, steam etc without consulting the supplier.

• Use a trolley with chipped or otherwise damaged wheel flanges.

• Obliquely side load a trolley.

Selecting the Trolley

Travelling trolleys are available in a range of capacities with load bars/suspension eyes to accept hook on blocks or built into the block as an integral part. They are available with push/pull, hand chain geared and power operated travel. Select the trolley to be used and plan the lift taking the following into account:

Capacity and type of trolley - load bar/suspension eye or built in block suspension arrangement - push/pull, hand geared or power operated travel. Type of block.

Track size and profile.

Consult the supplier if the trolley is to be used in areas of high risk, exposed to the elements, water, steam etc, with hazardous substances or subjected to extremes of temperature.

Storing and Handling Trolleys

Users will often remove blocks for storage leaving the trolley in place. They must be suitably protected from damage and corrosion. When removing trolleys for separate storage the following steps should be taken:

Never return damaged trolleys to storage. They should be dry, clean and protected from corrosion.

Store trolleys in a dry, clean area protected from damage. Operating chains, pendant power controls etc may be removed, clearly labelled and stored separately to avoid damage.

Trolleys should not be dropped or thrown down.

Installing and Commissioning

Follow any specific installation instructions issued by the supplier. These should be read in conjunction with the

instructions applicable to the block and should at least pay attention to the following:

Check the runway track is level, has an even running surface and is fitted with positive end stops which engage with the trolley frame or wheel treads.

Ensure the trolley is set to correct width with spacers equally disposed about the centre line, that the wheel profile is suitable for the track section and anti-tilt devices are correctly set.

If the trolley was dismantled for erection ensure the parts are correctly re-assembled. Ensure that all bolts, nuts etc are in place and fully tightened. If end stops were removed ensure they are replaced.

Using Trolleys Safely

The safe use of the trolley will largely be governed by the requirements for the block with which it is to be used but should take the following matters into account:

Do not use defective trolleys, blocks or accessories.

The trolley must be placed directly over the centre of gravity of the load. Under no circumstances must they be obliquely side loaded as this will cause them to tip, resulting in damage to the track or the trolley becoming detached from the track and falling.

In the case of push/pull trolleys push rather than pull suspended loads taking care to avoid swinging loads.

In-service Inspection and Maintenance

Maintenance may be combined with that of the block but should ensure that the trolley is clean and that moving parts are regularly lubricated. Keep the running surface of wheels and contact surface of track free of any contamination including lubricants.

Regularly inspect the trolley and, in the event of the following defects, refer the trolley to a Competent Person for thorough examination: wear; damage to wheel treads and flanges; insecure wheels and axle pins; loose nuts; distorted side plates, load bar or suspension eyes; damaged or worn hand chain; damaged controls; worn, chipped drive gears; illegible markings.