An electric chain hoist is a mechanical lifting device used to raise and lower heavy loads vertically. It is commonly used in industrial and commercial settings to facilitate the movement of materials and equipment. Electric chain hoists are known for their efficiency, durability, and ease of operation. Here are some key features and components of an electric chain hoist:

- Chain: The chain is a crucial component of the hoist and is used to lift and lower the load. It is typically made of high-strength alloy steel and is available in various sizes and lengths to match the lifting capacity of the hoist.

- Hoist Motor: The electric chain hoist is powered by an electric motor that provides the necessary force to lift the load. These motors are designed for heavy-duty operation and can handle a wide range of loads.

- Controls: Electric chain hoists come with control mechanisms that allow operators to raise, lower, and sometimes move the load horizontally. Control options include pendant controls, push-button controls, or remote controls, depending on the specific model.

- Gearbox: The gearbox is responsible for transmitting power from the motor to the chain drum, which in turn lifts or lowers the load. It ensures smooth and controlled movement.

- Chain Drum: The chain drum is a cylindrical component around which the lifting chain is wound. When the motor rotates the drum, the chain is either wound up or paid out to raise or lower the load.

- Safety Features: Safety is a paramount concern with electric chain hoists. They often come equipped with safety features such as overload protection to prevent lifting loads beyond the rated capacity, limit switches to prevent over-travel, and emergency stop buttons for immediate shutdown in case of an emergency.

- Lifting Capacity: Electric chain hoists are available in a wide range of lifting capacities, from a few hundred pounds to several tons. The specific capacity should match the requirements of the application.

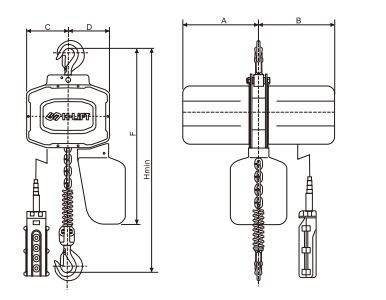

- Mounting Options: Electric chain hoists can be mounted in various ways, including fixed mounting on a beam, trolley mounting for horizontal movement, or as part of a more complex crane system.

- Duty Cycle: The duty cycle of an electric chain hoist refers to the amount of time it can operate continuously without overheating. Different hoists are designed for different duty cycles, with some suitable for continuous use and others for intermittent use.

- Voltage and Power Supply: Electric chain hoists are available in different voltage configurations to match the electrical infrastructure of the facility where they will be used.

Electric chain hoists are widely used in manufacturing, construction, warehouses, and various other industries where heavy lifting is required. When selecting an electric chain hoist, it's important to consider factors such as lifting capacity, control options, safety features, and compatibility with the intended application. Proper training and adherence to safety guidelines are essential when operating electric chain hoists to ensure safe and efficient material handling.

How to choose a right electric chain hoist?

- Load weight- The load to be lifted determines what hoists you have to buy.

- Lifting speed- You need to calibrate it for the successful loading and unloading process of materials.

- Your work environment- Some factory environments may cause abrasion for your machinery. For instance, under a very high-temperature condition, your hoist can start malfunctioning. Similarly, very low-temperature level results in cracks and freezing issues of internal parts. The frequent fluctuation of temperature is another risk of your system, and you can face the risk of short circuits.

- Height of your lift- You want to lift your load up to a height. This factor is important to choose the right hoist model. There is a chain container with electric hoist. The increased height denotes a longer chain and a bigger container. However, too much large containers can turn out to be a barrier to your load lifting process.

- The duty cycle- It indicates the duration for which you will use the hoist. This factor has a relation to longevity. Thus, the duty cycle length is one of the important things, as your system has to disperse heat from motors.