ALWAYS:

• Store and handle lifting clamps correctly.

• Inspect lifting clamps and accessories before use and before placing into storage.

• Put the clamp onto the plate as far as it will go.

• Check that the clamp is directly over the centre of gravity of the load.

• Ensure the clamp is fully locked or tightened onto the plate before lifting.

• Take great care to ensure the plate is fully supported before attempting to release the clamp.

NEVER:

• Use lifting clamps on hard or polished plate unless they have been specifically designed for that purpose.

• Put packing between the plate and the jaws of the clamp.

• Attempt to lift more than one plate in the clamp.

• Lower from the vertical to horizontal or vice-versa unless the clamps have been designed for that purpose.

• Obliquely load vertical lifting clamps.

• Force or wedge the hook of the lifting appliance into the eye of the clamp.

Selecting the Correct lifting clamp

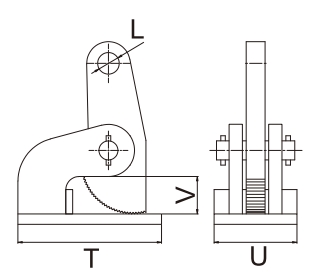

Vertical lifting clamps are available in a range of capacities and designs. They may utilise a lever, cam mechanism, roller or screw to provide friction grip to the plate. Select the lifting clamp to be used and plan the lift taking the following into account:

Type of clamp - lever, cam, roller or screw action.

Capacity and plate thickness.

If a pendant chain sling is required.

NOTE 1: Some designs of clamp, particularly those with a moving cam action jaw where the initial grip is provided by a spring, have a minimum load and minimum plate thickness they can safely lift. Wherever possible refer to the manufacturer’s instructions but in the absence of specific guidance the load should not be less than 20% of the SWL and the plate thickness not less than 20% of the maximum.

NOTE 2: Some designs of lifting clamp are suitable for lifting plates from the horizontal to the vertical and the inclusion of a pendant chain to provide articulation between the clamp and lifting hook is essential. However the use of pendant chains should always be considered to prevent the hook weight being imposed on the clamp as this might cause the clamp to be released.

Storing and Handling lifting clamps

Never return damaged or dirty lifting clamps to storage. They should be dry, clean and protected from corrosion.

lifting clamps should not be dropped or thrown down.

Using lifting clamps Safely

Do not use defective lifting clamps, or accessories.

Do not use the clamp to lift a load less than 20% of the SWL or with a thickness less than 20% of the maximum unless the manufacturer’s instructions permit otherwise.

Position the clamp correctly. Place the clamp over the load centre of the plate. If the plate is long and has a tendency to bend, use two clamps equally disposed about the centre of gravity in conjunction with a spreader beam. Care must be taken to ensure no one clamp takes more than its SWL.

Put the clamp onto the plate as far as it will go.

Under no circumstances should packing be placed between the plate and the jaws nor any attempt made to lift more than one plate in the clamp.

Do not use clamps at an angle to the edge of the plate or for lowering from vertical to horizontal, or vice-versa, unless they are designed for the purpose.

Keep oil, grease and similar contaminates away from jaws which use a friction grip material to hold the plate.

In-service Inspection and Maintenance

Vertical lifting clamps should be cleaned and any moving parts lubricated at appropriate intervals, unless the suppliers specific instructions indicate otherwise.

In the case of clamps with smooth jaws lined with a friction material, care must be taken to ensure no lubricant comes into contact with the friction material.

Regularly inspect the lifting clamp and, in the event of the following defects, refer the clamp to a Competent Person for thorough examination: wear, damage or distortion to fixed and moving jaws; frame opening out or cracked; insecure, worn or bent pins, bolts etc; worn friction grip material; damaged, bent or unsatisfactory acting locking lever; tight, bent or damaged clamping threads etc; corrosion; illegible marking.

WARNING: Teeth of jaws must not be re-sharpened or re-cut unless this has been specifically approved by the maker.