A motorized trolley for an electric chain hoist is an essential piece of equipment used to facilitate the movement of heavy loads vertically and horizontally. This trolley is specifically designed to work in conjunction with an electric chain hoist, which is commonly used in industrial settings for lifting and lowering heavy objects.

Here are some key features and functions of a motorized trolley for an electric chain hoist:

- Load Capacity: Motorized trolleys are designed to handle different load capacities, ranging from a few hundred pounds to several tons. The capacity of the trolley should match or exceed the capacity of the electric chain hoist it is paired with.

- Electric Drive: These trolleys are equipped with an electric motor that provides horizontal movement along a beam or track. The electric drive system allows for precise control when positioning the load.

- Control System: Motorized trolleys typically come with control systems that allow operators to move the hoisted load forward, backward, left, and right. They may have pendant controls or remote controls for ease of operation.

- Safety Features: Safety is a critical consideration when handling heavy loads. Motorized trolleys often feature safety mechanisms such as limit switches to prevent over-travel, emergency stop buttons, and overload protection.

- Beam Compatibility: Motorized trolleys are designed to fit specific types of beams or tracks, such as I-beams or overhead crane tracks. It's important to ensure compatibility with the existing infrastructure.

- Speed and Precision: The trolley's electric motor allows for variable speed control, enabling precise positioning of the load. This is especially important when working with delicate or sensitive materials.

- Versatility: Motorized trolleys can be used in various industrial applications, including manufacturing, construction, warehouses, and maintenance facilities.

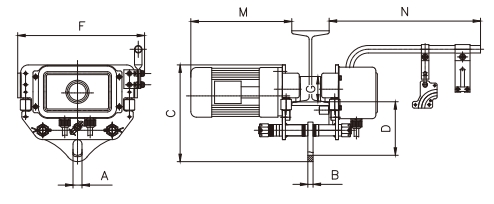

- Mounting Options: Depending on the design, motorized trolleys can be mounted on the top of the beam (top-running trolley) or suspended from the bottom of the beam (under-running trolley).

- Power Source: Motorized trolleys are typically powered by electricity.

When selecting a motorized trolley for an electric chain hoist, it's important to consider factors such as load capacity, the type of beam or track in your facility, safety features, and the specific requirements of your application. Additionally, proper training and adherence to safety guidelines are crucial when operating these trolleys to prevent accidents and ensure the safe handling of heavy loads.