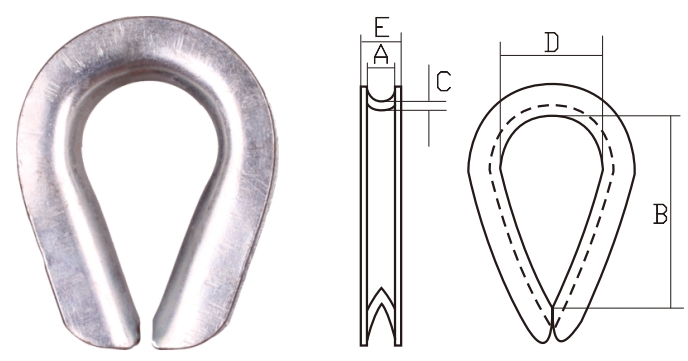

U.S. Type Heavy Duty Wire Rope Thimble

- Wire rope thimbles, cable thimbles or wire thimbles, are used to support wire rope eyes by creating a durable wear surface when connected to mating rigging hardware.

Thimbles are used to protect the eyes of cable, and rope slings from abrasion by providing a solid steel barrier between the fragile cable strands and the other rigging fitting used in the connection.

- Finish: Electric galvanized or hot dip galvanized.

- Standard: Federal Specification FF-T-276b Type III.

- Sizes up to 4'' are available.

How to use wire rope thimble?

- Wire rope thimbles are used in conjunction with cable and rope to protect the eyes and will allow for smooth rope guiding around natural curves. So that the most important thing is to make sure the thimble eye securely fastened. Here are some tips for correctly using wire rope thimble:

- To know the right rope thimble size to the cable, for example when you are using 1/2″ uncoated rope cable, use a 1/2″ wire rope thimble.

- Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized rigging fittings.

- While you are using a vinyl coated cable, you should multiply the actual size of the cable, usually use a larger size thimble than normal, for the actual diameter is the thickness of the vinyl coating plus the inside wire rope diameter. For example, if you are using a 5/16″ vinyl coated cable that is coated to 3/8″ diameter, you’d want to use a 3/8″ wire rope thimble.

| Item No. |

Size |

Dimensions(inch) |

Weight |

Product Code |

| A |

B |

C |

D |

E |

kg |

| WRTHD006 |

1/4″ |

0.28 |

1.62 |

0.06 |

0.88 |

0.41 |

0.025 |

604001006 |

| WRTHD008 |

5/16″ |

0.34 |

1.88 |

0.08 |

1.06 |

0.50 |

0.044 |

604001008 |

| WRTHD010 |

3/8″ |

0.41 |

2.12 |

0.11 |

1.12 |

0.63 |

0.086 |

604001010 |

| WRTHD011 |

7/16″ |

0.47 |

2.38 |

0.12 |

1.25 |

0.72 |

0.11 |

604001011 |

| WRTHD013 |

1/2″ |

0.53 |

2.75 |

0.14 |

1.50 |

0.81 |

0.205 |

604001013 |

| WRTHD014 |

9/16" |

0.59 |

2.75 |

0.15 |

1.50 |

0.89 |

0.205 |

604001014 |

| WRTHD016 |

5/8″ |

0.66 |

3.25 |

0.16 |

1.75 |

1.00 |

0.27 |

604001016 |

| WRTHD019 |

3/4″ |

0.78 |

3.75 |

0.22 |

2.00 |

1.22 |

0.55 |

604001019 |

| WRTHD022 |

7/8″ |

0.94 |

4.25 |

0.22 |

2.25 |

1.38 |

0.80 |

604001022 |

| WRTHD026 |

1″ |

1.06 |

4.50 |

0.25 |

2.50 |

1.56 |

1.0 |

604001026 |

| WRTHD032 |

1-1/8"-1-1/4″ |

1.31 |

5.12 |

0.25 |

2.88 |

1.88 |

1.47 |

604001032 |

| WRTHD036 |

1-1/4"-1-3/8″ |

1.44 |

6.25 |

0.37 |

3.50 |

2.25 |

3.4 |

604001036 |

| WRTHD038 |

1-3/8"-1-1/2″ |

1.56 |

6.50 |

0.50 |

3.50 |

2.62 |

4.5 |

604001038 |

| WRTHD042 |

1-5/8″ |

1.72 |

8.00 |

0.50 |

4.00 |

3.00 |

5.67 |

604001042 |

| WRTHD045 |

1-3/4″ |

1.84 |

9.00 |

0.50 |

4.50 |

3.06 |

6.9 |

604001045 |

| WRTHD050 |

1-7/8"-2″ |

2.09 |

12.00 |

0.50 |

6.00 |

3.38 |

9.45 |

604001050 |

| WRTHD056 |

2-1/4″ |

2.38 |

14.00 |

0.62 |

7.00 |

3.88 |

17.6 |

604001056 |