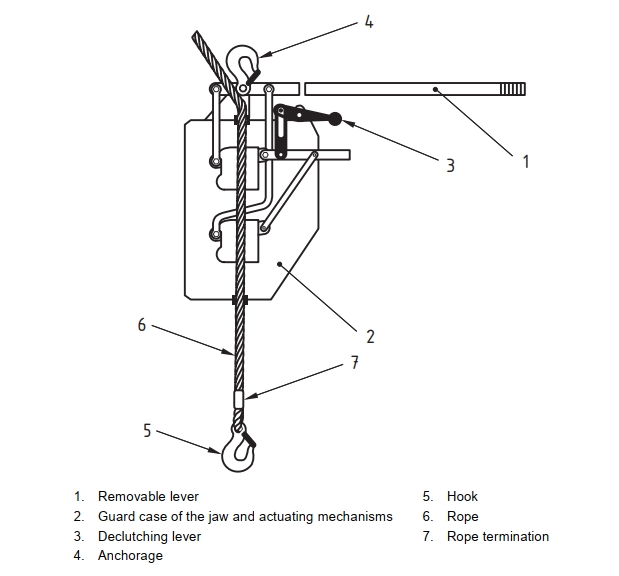

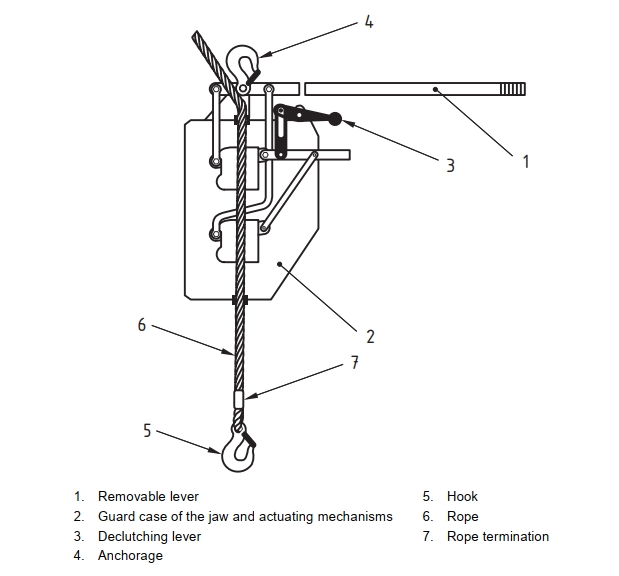

Jaw winch is a device for lifting, lowering and holding a load by means of a rope, where the rope is gripped or moved by jaws using human effort on a lever or levers.

Operation cycles is a lifting movement plus a lowering movement over the minimum vertical distance defined by the rope length corresponding to its passing over all concerned jaw winch parts.

The mechanical strength of jaw winches shall be checked by an appropriate calculation method. Jaw winches shall a coefficient of utilisation of at least 4:1

The lifting lever shall be fitted with a device which limits the effort applied through this lever. The setting of this device shall limit the lifting force to not more than 2 times the rated capacity.

The jaw winch shall withstand 400 cycles with the rated capacity with no failure, no replacement of parts, no resting time, except for lubrication of the rope.

ALWAYS:

• Store and handle wire rope pulling hoists correctly.

• Inspect the machine, rope and accessories before use and before placing into storage.

• Ensure mounting and suspension points are secure and suitable for the full loads that will be imposed.

• Ensure the machine is free to align correctly with the rope and the rope is free of any obstructions.

• Use only the correct rope supplied for the machine.

NEVER:

• Use kinked, damaged ropes or ropes with broken wires.

• Extend or force operating levers.

• Operate raising and lowering levers at the same time.

• Use wire rope pulling hoist if the rope is twisted or trapped.

• Use wire rope pulling hoist for man-riding applications unless they are specifically designed/adapted for that purpose.

Selecting the Correct Wire Rope Pulling Hoist

Wire rope pulling hoists are available in a range of capacities, with manual operation (hydraulic operation is available for certain applications) for both lifting and pulling duties. Various rope lengths are available. Select the machine to be used taking the following into account:

Type of machine - manual, hydraulic - lifting or pulling capacity - length of rope and need for rope collecting/coiling.

Rigging arrangement - diverters, pulley blocks - anchorage and suspension points - imposed loads.

Consult the supplier if the machine is to be used for man-riding applications.

Storing and Handling Wire Rope Pulling Hoists

Never return damaged wire rope pulling hoists, ropes etc to storage.They should be dry, clean and protected from corrosion.

Rope should be carefully coiled onto a suitable drum or frame for storage, taking care to avoid any twists.

Store machines and ropes on a suitable rack, not on the floor where they may be damaged.

Installing and Commissioning

Follow any specific instructions for installation and commissioning issued by the supplier and the general requirements given overleaf.

Using Wire Rope Pulling Hoists Safely

Do not use defective wire rope pulling hoists, ropes, pulleys etc.

Check the rigging arrangement, that anchorage and suspension points are secure and adequate for the imposed loads.

Ensure the correct rope is fitted and that it is not twisted or kinked. The machine must be free to align with the rope.

For lifting operations do not exceed the marked SWL. The line pull must not exceed that stated for pulling applications.

Only use the operating lever provided with the machine and do not extend this with tubes etc. Undue force will damage the machine or cause safety pins to shear.

Do not attempt to operate the raising and lowering levers at the same time.

For man-riding applications only use a machine which has been designed or specially adapted for that purpose, following the suppliers specific instructions. Additional safety equipment will be necessary.

In-service Inspection and Maintenance

Follow the specific instructions for maintenance issued by the supplier. These should be incorporated into the site

maintenance programme observing any particular needs due to the site or working conditions. Lack of lubrication will result in a jerky movement or failure to operate. Keep the machine well lubricated. It is impossible to over lubricate wire rope pulling hoists.

Regularly inspect the wire rope pulling hoist and rope and, in the event of the following defects, refer the machine to a Competent Person for thorough examination: casing damaged or distorted; shear pins distorted or broken; operating lever bent or distorted; incorrect diameter sheaves used in association with rope; incorrect rope fitted; rope is kinked, worn, corroded or has broken wires; wire rope termination is damaged, cracked or pulled; terminal fittings damaged, distorted, cracked or gouged; marking illegible; jerky operation; any other visual defects or operational faults.