Permanent Magnetic Lifter

PRINCIPLES FOR THE SELECTION OF MAGNETIC LIFTERS

Applications

Magnetic lifters can be suitable for a variety of applications. Some may be used as general purpose lifting accessories, and therefore require their capacity to be assessed for each application, whereas others may be dedicated to a single application and are selected specifically for it. However not every load with ferromagnetic properties can safely be handled with a magnetic lifter.

The magnetic lifter selected must match the characteristics of the load. As well as the weight, this includes the shape, surface finish and magnetic properties of the load.

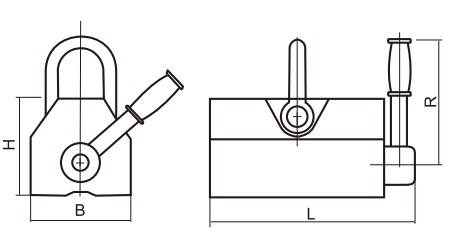

The shape of the magnet should be compatible with that of the load. For example, a magnet with a flat face can handle sheet material whereas for lifting round section material, a magnet with a V shaped recess in the face is more suitable. For long loads, an arrangement of several magnets used in conjunction with a lifting beam is generally suitable as it provides the load with adequate support along its length. The position and capacity of the individual magnets should be such as to ensure that the share of the load imposed on each does not exceed its working load limit. For flexible loads, the positioning should provide support at short enough spaces to prevent the load from peeling off the magnet.

Lifting magnets are normally rated for lifting a horizontal load in the vertical plane only. If the line of pull is not at right angles to the plane of the load, their lifting capacity will be substantially reduced and slippage may occur.

For such applications, the advice of the manufacturer should be obtained.

Consideration should be given to the following:

(1) Lifting capacity required

(2) Characteristics of the load in terms of shape, surface finish and magnetic properties.

(3) Nature of the lifting operation.

(4) Lifting machine it is to be used with.

(5) Available headroom.

(6) Self weight of the magnetic lifter and degree of portability required.

(7) Method of control and control features required.

(8) Electrical requirements for electro or electro-permanent magnetic lifters.

(9) Proximity of persons during operations.

(10) Backup and other safety features required.

(11) The documentation required by legislation. If this is not on record, refer the magnetic lifter to a Competent

Person for thorough examination