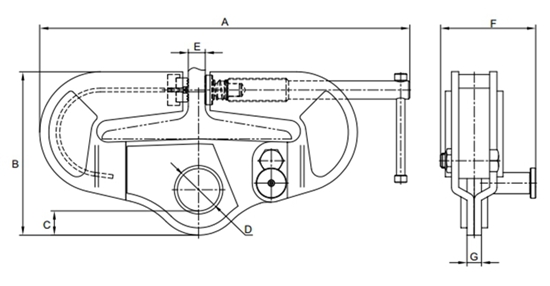

H-Lift Beam Clamp/Girder Clamp

ALWAYS:

• Store and handle beam clamps correctly.

• Inspect beam clamps and accessories before use and before placing into storage.

• Ensure the supporting structure is adequate for the full load that will be imposed and suitable for the application.

• Check the clamp is of the correct profile and size, or correctly adjusted, for the beam width and that it seats correctly on the beam flange.

• Ensure the beam clamp is strong enough for the full load that will be imposed.

• Check that the clamp is directly over the centre of gravity of the load.

NEVER:

• Use beam clamps which are unidentified or uncertified for lifting applications.

• Never replace bolts, shackles etc without consulting the supplier.

• Throw or drop beam clamps.

• Use beam clamps on damaged or distorted beams.

• Force or wedge hooks of lifting appliances into the attachment eye or fitting (eg shackle).

• Obliquely load beam clamps without the authority of the supplier.

Selecting the Correct Beam Clamp

Beam clamps are available in a range of capacities and designs. They may be adjustable or of fixed size, have scissor action, screw locking or bolt clamp fixing and be suitable for temporary or permanent applications. Select the beam clamp to be used and plan the lift taking the following into account:

Type of clamp - adjustable/non-adjustable - scissor, screw or bolt action.

Capacity and beam size or range of beam sizes.

Suitability of the beam.

Type of lifting appliance to be used.

If application is temporary or permanent.

NOTE: Beam clamps are generally intended for attachment to overhead beams to act as suspension points for lifting

appliances. Some designs are suitable for attachment to the load to provide a lifting point. The supplier should be consulted for such applications which are excluded from these instructions.

Storing and Handling Beam Clamps

Never return damaged beam clamps to storage. They should be dry, clean and protected from corrosion. Where necessary fasteners should be reassembled immediately after removal from the beam.

Beam clamps should not be dropped or thrown down.

Using Beam Clamps Safely

The safe use of beam clamps will largely be governed by the requirements for the lifting appliance with which it is to be used but should take the following matters into account:

Do not use defective beam clamps, lifting appliances or accessories.

Ensure the structure from which the clamp is to be suspended is undamaged and is adequate for the full load that will be imposed. If any doubt exists consult a Competent Person to confirm suitability.

Ensure the clamp is suitable for the application, correct size and profile for the beam and seats correctly. It must not cause localised overloading.

Ensure the lifting appliance is compatible with the clamp and that hooks or other attachments fit freely into the eye, shackle etc of the clamp.

The clamp must be positioned directly over the centre of gravity of the load and the load must not be allowed to swing or impose an oblique loading.

If two clamps are to be used in tandem the use of ancillary equipment may also be necessary, eg spreader beam. Care must be taken to ensure no one clamp takes more than its SWL.

In-service Inspection and Maintenance

Beam clamps should be cleaned and any moving parts lubricated at appropriate intervals unless the suppliers specific instructions indicate otherwise.

Regularly inspect the beam clamp, in the event of the following defects refer the clamp to a Competent Person for thorough examination: wear, damage or distortion, cracks, insecure bolts etc, corrosion, illegible markings.